Welcome to Romark Engineering, your bespoke metalwork fabrication experts. Whatever your requirements, from the basic concept through to the finished project, we will use our expertise to fulfil your needs. We work to critical deadlines where a high-quality finished project is key. Our skilled engineers can produce hand-made prototype parts as well as parts for production and pre-production runs. Please don’t hesitate to get in touch with us today for a quote on any of our services.

YEARS OF EXPERIENCE

BESPOKE METALWORK FABRICATION

100% SATISFACTION

Romark Engineering | Folding & Pressing

Bespoke Metal Folding & Pressing

Metal folding is the process of bending and shaping sheet metalwork. Pressing (or stamping) is the creation of a shape in metal. Punching, blanking, bending, coining, embossing, and flanging are all pressing techniques used to shape the metal. Before the metal can be folded or pressed, we use CAD engineering technology to ensure optimisation and accuracy.

CNC Controlled Folding & Pressing

Ahead of folding and pressing, we use Computer Numerical Control (CNC) machinery and Computer-Aided Design (CAD) software to create precise specifications. Our advanced machinery is used to create precise metal parts and components by controlling a range of complex machinery, from grinders and lathes to mills and CNC routers.

We offer a 2D and 3D CAD service for various uses, from reverse engineering projects to producing drawings for manufacture. Manufacturing for both one-off and production volumes for the automotive, power and architectural industries, our highly skilled workforce produces prototype parts and pressed parts for production runs.

We Fabricate and Supply…

Complex Facades | Balconies | Architectural Canopies Barriers & Bollards | Balustrades

Cladding & Screening Modular | Disabled Access Ramps & Handrails | Metal Stairways

Steel Gate and Fencing | Brackets & Supports Pipework | Structural & Architectural Steelwork

Gates (Inc automated), Posts, Railings & Window Grills | Security Door & Window Grills

Fire Escape Stairways & Roof Ladders Fabricated | Special Gutter & Drainage Systems Fabricated

Stainless Steel Splashbacks, Worktops, Doors & Panels | One-offs & prototypes | And more!

With a team of highly skilled and experienced engineers, we offer a complete service for the design and manufacture of a large range of metal products. From hand-made prototype parts to production and pre-production runs for a wide range of industries, we can do it all. Contact us for a quote today!

What are the benefits of CNC Machining?

Accuracy & Zero Defects

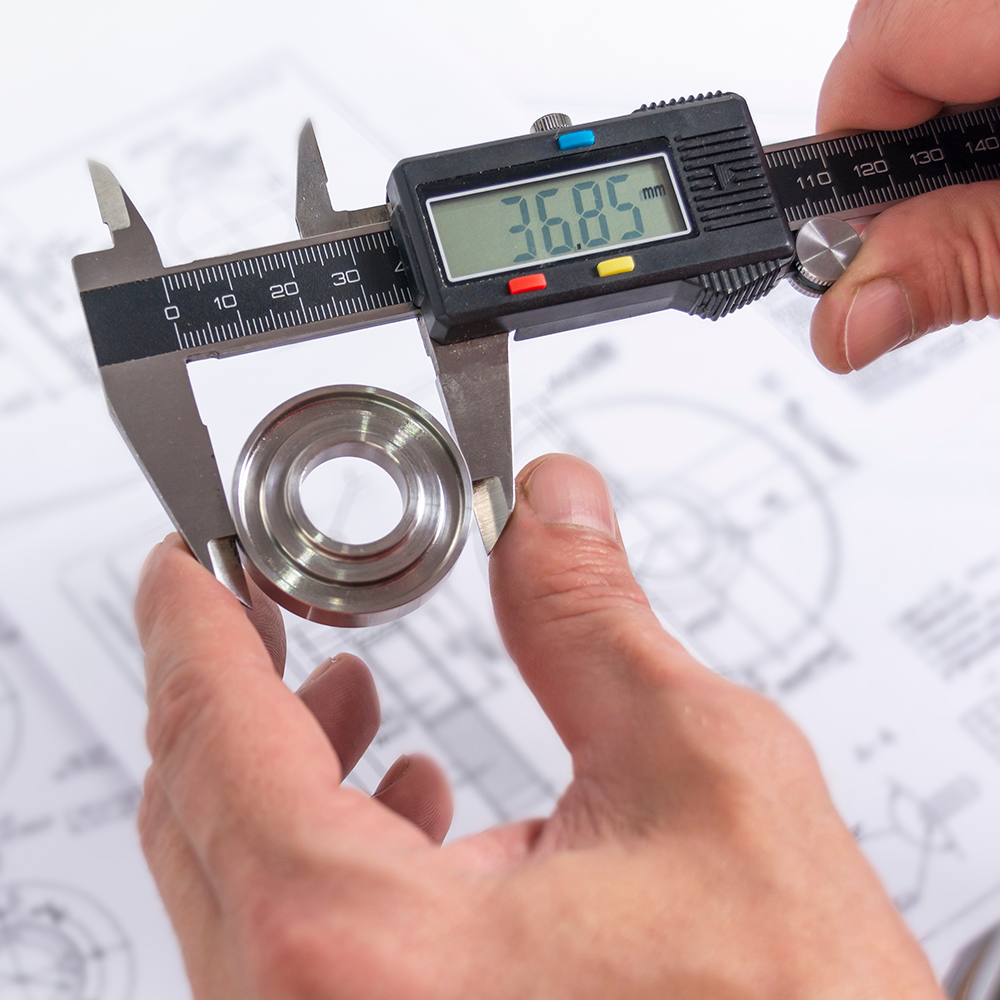

We programme the desired cuts into the software programme, which are then dictated to the corresponding tools and machinery. This means that all dimensional tasks are carried out to precise specifications with zero defects.

Variety

CNC Machining allows for design development, alteration and optimisation for a range of parts and components. From prototype parts as well as parts for production and pre-production runs, CNC machinery can do it all.

Productivity

CNC machining can be activated on their fastest settings to match increased demands. Additionally, these machines can run24 hours a day, seven days a week without needing a break.

Efficiency

Using One CNC CAD-CAM, a market leader programming system, we deliver high quality, tight tolerances and improved efficiency. You can trust that your products are in safe hands with us.

Cost-Effective

Our CNC machinery is highly cost-effective. As the machinery is so accurate, waste is kept to a minimum and no raw materials will be thrown away. This means that you will save money every time you come to us.

The Latest Technology

Combining highly skilled and experienced engineers with the latest technology we offer a range of bespoke metal products and components. We also outsource a range of services including powder coating, wet spray, electroplating, galvanising, and laser cutting 2D and 3D. Our range of advanced machinery includes:

Amada LC Alpha IV 4Kw CO2 Laser | Amada 220-4 7 Axis 4000mm CNC Press Brake |

Amada 100-3 7 Axis 3m 100ton CNC Press Brake | XYZ 710 CNC Machining Centre

Trumpf Trushear 3000mm 6mm Guillotine | Sheet & Plate Power Rollers Up To 6mm Steel

Ward Forsyth 50ton Electro Hydraulic C Frame Deep Draw Press | Bridgeport Mill With D.R.O

Harrison M300 600mm Lathe With D.R.O | Bianco Vertical Semi-Automatic 300mm Band Saw

Arboga Linisher 2000mm X 150mm Belt | Arboga Linisher 2000mm X 50mm Belt

2 Medding Pillar Drill | 6 Tig Welders AC/DC | 6 Mig Melders For Steel, Alu & Stainless

Hypetherm Hand Plasma Cutter | Aqua Blasting Cabinet | Hyster 2.5 Ton Forklift

Various Inspection Equipment | Solid works, Autocad, Rhino3D & One CNC CAM Software

Why work with us?

Years of Experience

Our team of specialist engineers have years of experience working within the engineering industry. Whatever your requirements, we use our expertise to fulfil your requirements every time you come to us.

Customer Satisfaction

We work to critical deadlines and tight tolerance where a high-quality finished project is key. We are focused on your satisfaction and offer a complete service for the design and manufacture of a large range of metal products.

Range of Services

Manufacturing for both one-off and production volumes for the automotive, power and architectural industries, our highly skilled workforce produces prototype parts and pressed parts for production runs.

If you’re looking for professional, precise & cost-effective bespoke metalwork fabrication, get in touch with us today for a quote!

Need a service & ready to book?Call us 01375 640 037

Contact Us

Get In Touch

Contact Info

jobs@romarkengineering.com

Unit 8+9 Baryta Close,

Stanford-Le-Hope,

Essex, SS17 0JE